Oligonucleotides: A Cornerstone for Therapeutics & More

ISPE

OCTOBER 27, 2022

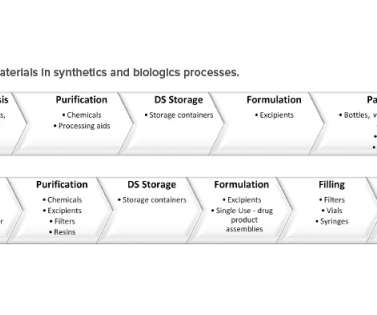

As a result, some companies have challenged the paradigm by forgoing lyophilization entirely, opting to provide solution phase API to drug product facilities for filling and packaging. Combining the incremental process improvements previously mentioned results in an optimized facility, with the adjusted block flow shown in Figure 5.

Let's personalize your content