Considerations for a Decentralized Manufacturing Paradigm

ISPE

SEPTEMBER 11, 2023

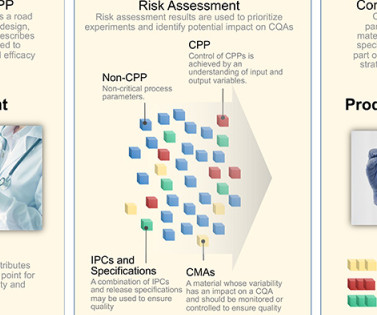

4 , 5 Additionally, reducing shipping limitations—such as packaging, storage, and transportation durations—helps speed up patient access in certain instances while ensuring there is no negative impact to the product’s critical quality attributes (CQAs). FDA Official Warns Manufacturers of Common Problems Found in Aseptic Operations.”

Let's personalize your content